UNPAVED ROADS AND TEMPORARY WORKING SURFACES

The required thickness of an unpaved road or working surface is principally a function of the traffic intensity it experiences (magnitude of axle load, number of vehicle passes) and the shear strength of the underlying subgrade – more intense traffic and weaker subgrades result in a requirement for thicker aggregate layers.

For a given set of design conditions BX Geogrids can be used to reduce the required aggregate thickness by up to 60%. This results in:

- Initial cost savings typically in the range of 40-50%

- Faster construction

- More environmentally friendly or “greener” construction methods – 20 to 40% reduction in the carbon emissions associated with the road construction.

RAIL

STRUCTURES

BX Geogrids are approved for use by the American Railroad Engineering and Maintenance-of-Way Association (AREMA).

They can be used to:

- Reinforce the ballast layer extending the period between re-surfacing events by 3 to 5 times

- Reinforce the sub-ballast layer in order to reduce the required roadbed thickness and provide maximum initial cost savings – typically $30-50,000/linear mile of track

CONVENTIONAL AND

HEAVY-DUTY PAVEMENTS

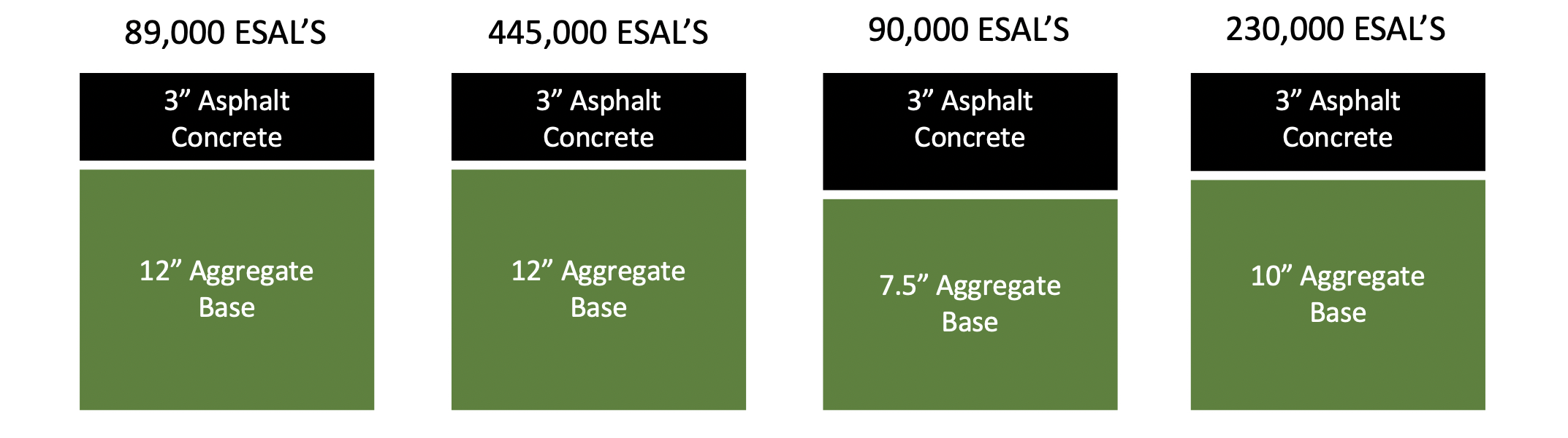

The same principles apply in both flexible and rigid pavements that incorporate a granular layer within the main pavement structure.

BX geogrids are typically used to provide one of the following benefits:

- Optimize the pavement section to provide maximum initial cost savings – typically 10-20%

- Maintain an existing pavement design but “beef it up” with a geogrid to extend its design life – typically 2- to 6-fold.

- Develop a cost-neutral solution i.e. provide some design life extension whilst ensuring there is no additional cost resulting from the use of the geogrid.

Allowable Traffic

Case Studies

INTERMODAL FACILITY, CHARLOTTE, NC

INTERMODAL FACILITY, CHARLOTTE, NC

OWNER: Norfolk Southern Corp.

ENGINEER: Patrick Engineering

CONTRACTOR: Milord Company

PRODUCTS: PacCor BX Type 2

» DETAILS

The heavy-duty pavements constructed adjacent to the rail tracks in this facilitate are required to carry extremely high wheel loads. A layer of geogrid placed at the bottom of the aggregate layer helped reduce the required thickness of the overlying roller-compacted concrete.

US25 – LEXINGTON TO GEORGETOWN ROAD, KY

US25 – LEXINGTON TO GEORGETOWN ROAD, KY

OWNER: The Kentucky Transportation Cabinet (KYTC)

CONTRACTOR: ATS Construction, Lexington, KY

PRODUCTS: PacCor BX Type 1

» DETAILS

This project involved the widening of an existing highway. The target grade for the new section of road was achieved by placing and compacting local embankment fill. A geogrid was then placed directly on top to provide additional stability to the overlying 12 inch thick unbound aggregate layer. Asphalt binder and an asphalt surface course made up the rest of the pavement structure. The presence of the geogrid increases the life of the pavement significantly.

Although originally designed using a proprietary triaxial geogrid, the client agreed a switch to a more conventional biaxial geogrid which provided additional material cost savings with no loss of performance.

Other Geotextiles