Receiving, Handling & Installation Guide

Our Guide contains the following information:

Receiving & Handling

- Visual Inspection

- Unloading

- Storage (General)

- Storing Bell and Spigot

- Weather Considerations

- Stringing Pipe

Installation

- Introduction

- Initial Preparation

- Installation of Plain End Pipe

- Installation of Bell and Spigot

- Field Cutting

- Transitions

- Curved Pipe Systems

Testing

- General Information

- Pipe Joint Testing

- Deflection Testing

Repairs

HDPE Pipe Specifications

HDPE CORRUGATED PLASTIC PIPE

Pacific Corrugated Pipe Company’s HDPE (High Density Polyethylene) pipe is a heavy-duty pipe for storm sewers, culverts, storm water storage, and water quality applications. Pacific Corrugated Pipe manufactures our StormTite™ brand utilizing both recycled and virgin resins in both type C – single wall with a corrugated interior and exterior, and Type S – double wall with a corrugated exterior and a smooth interior wall. We supply sizes to the market ranging from 4” to 60” in diameter. Both solid and perforated pipe are available. Type-S pipe is available with a plain end or an integral bell and spigot system. All other product specifications are listed on the back of this sheet.

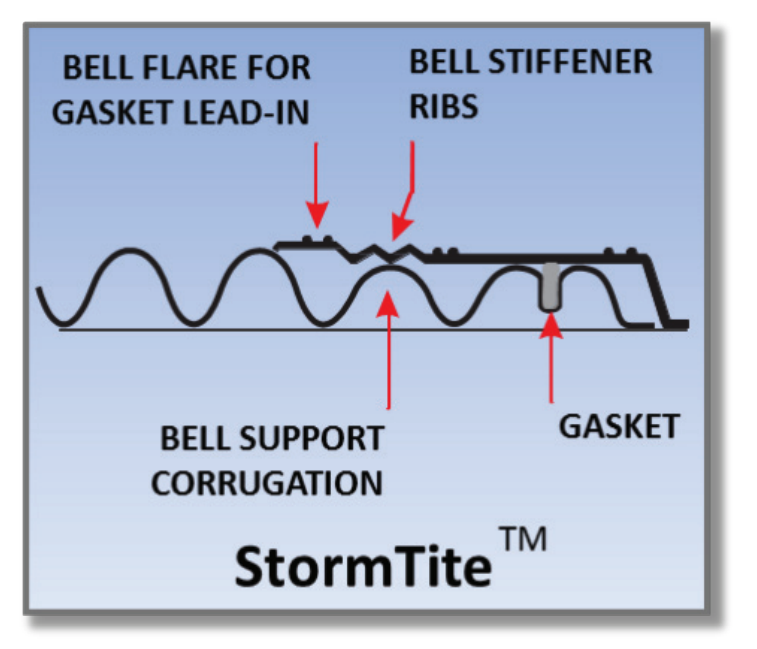

StormTite™ Bell and Spigot

StormTite™ Bell and Spigot

StormTite™ 10.8 psi bell and spigot joint systems for Type S pipe has been certified by independent third party laboratories to meet the “watertight” requirements defined in ASTM D-3212. This system eliminates the need for separate couplers without giving up strength or superior hydraulic flow.

Specifications

Products produced by Pacific Corrugated Pipe Co. (“PCP”) are marked with the relevant applicable standards to which they conform. Listed below are specifications commonly used within the corrugated HDPE pipe industry. Specifications can have multiple editions and are revised from time to time. The markings on pipe products indicate conformance to the latest edition and revisions of such standards as of the date of production.

- AASHTO M 252 – Standard Specification for Corrugated Polyethylene Drainage Pipe 3”-10” (75mm to 250mm)

- AASHTO M 294 – Standard Specification for Corrugated Polyethylene Pipe, 12”-60” (300mm to 1500mm)

- ASTM F 405 – Standard Specification for Corrugated Polyethylene (PE) Pipe and Fittings, 3”-6”

- ASTM F 667 – Standard Specification for 8 through 24 inch Corrugated Polyethylene Pipe and Fittings

- ASTM F 2306 – Standard Specification for 12 to 60 inch (300mm to 1500 mm) Annular Corrugated Profile-Wall Polyethylene Pipe and Fittings for Gravity-Flow Storm Sewer and Subsurface Drainage Applications

- ASTM F 2648 – Standard Specification for 2 to 60 inch (50 to 1500mm) Annular Corrugated Profile Wall Polyethylene (PE) Pipe and Fittings for Land Drainage Applications (virgin and recycled resins)

- ASTM D 2321 – Standard Practice for Underground Installation of Thermoplastic Pipe for Sewers and Other Gravity-Flow Applications ASTM D 3350 – Standard Specification for Polyethylene Plastics Pipe and Fittings Materials

- ASTM F 477 – Standard Specification for Elastomeric Seals (Gaskets) for Joining Plastic Pipe

- ASTM D 3212 – Standard Specification for Joints for Drain and Sewer Plastic Pipes Using Flexible Elastomeric Seals

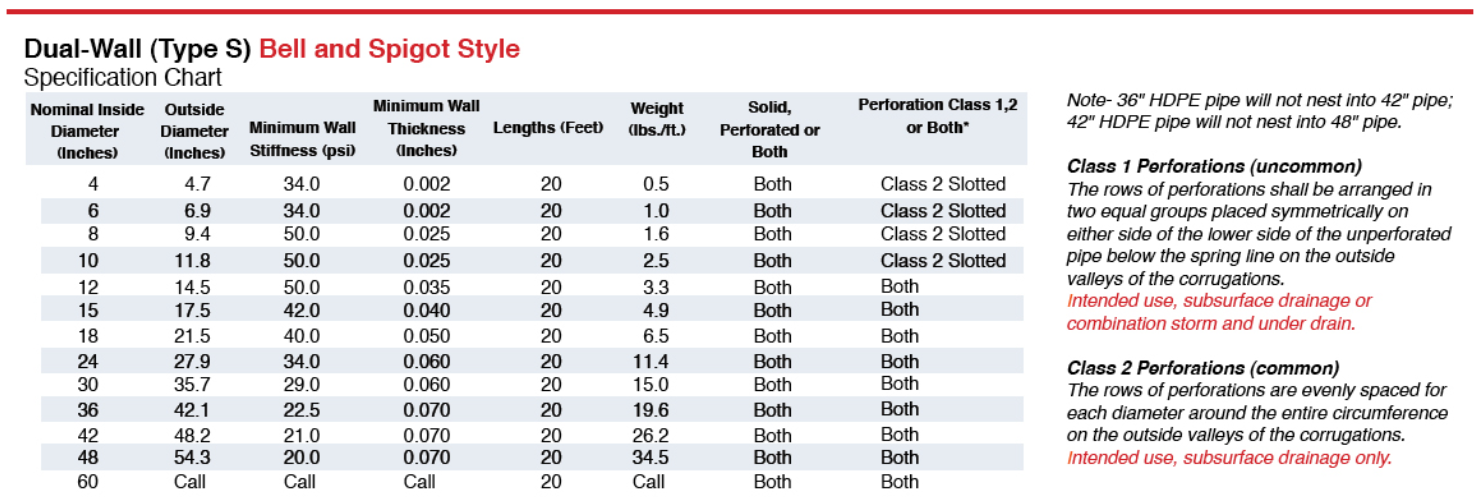

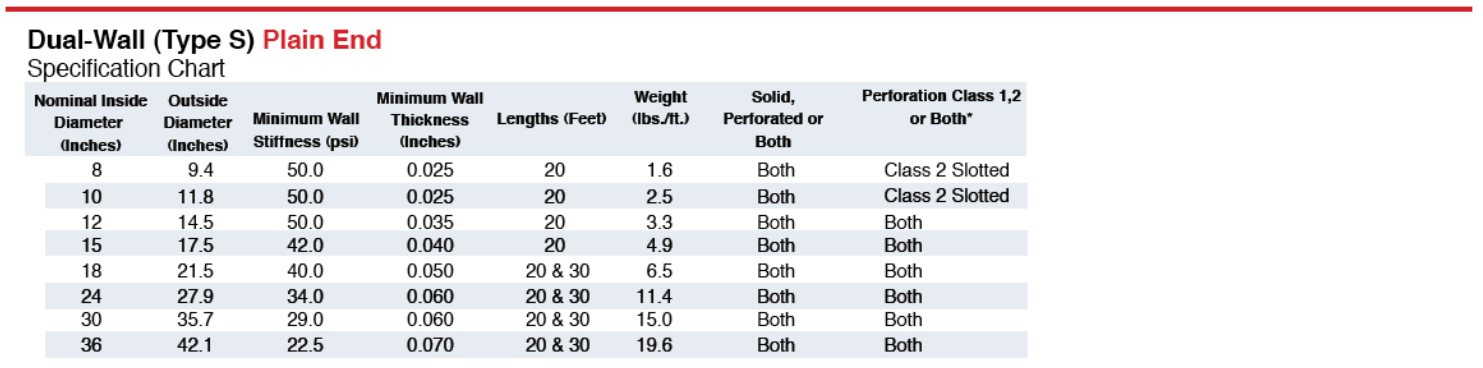

StormTite™, our 10.8 psi bell and spigot joint system has been certified by independent third party laboratories to meet “watertight” requirements defined in AASHTO M-294 and all applicable ASTM specifications including ASTM-3212. This system eliminates the need for separate couplers without giving up strength or superior hydraulic flow. This ease of installation of StormTite™, combined with its light weight and longer sections, ensures project savings over heavier materials such as reinforced concrete pipe (RCP). Using Pacific Corrugated HDPE pipe can lower your overall project construction costs as a result from the utilization of smaller crews, faster installation, easier handling of lightweight pipe and smaller equipment. Sizes in the following tables outline our entire product line of pipe that are available with a plain end or integral bell and spigot joint system for pressure applications:

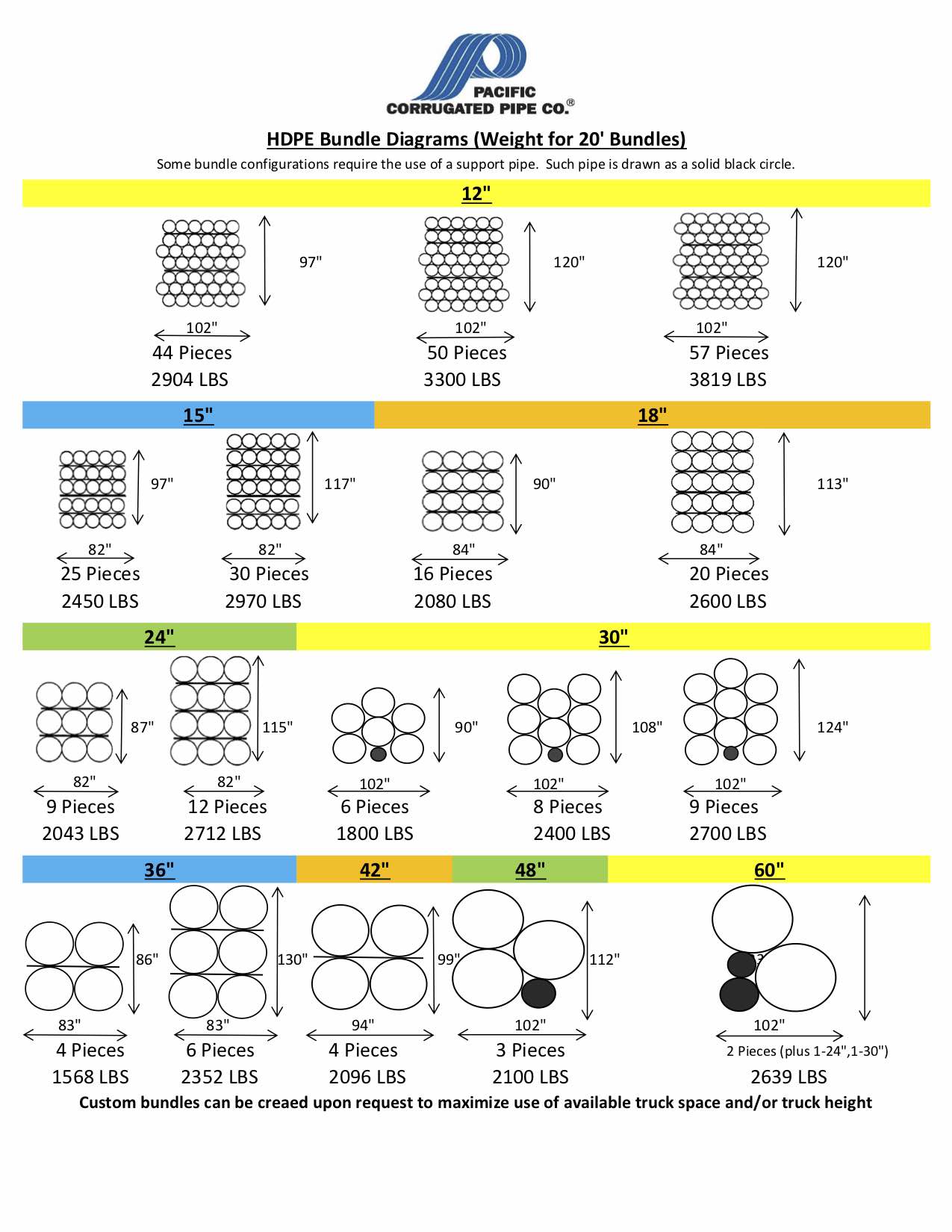

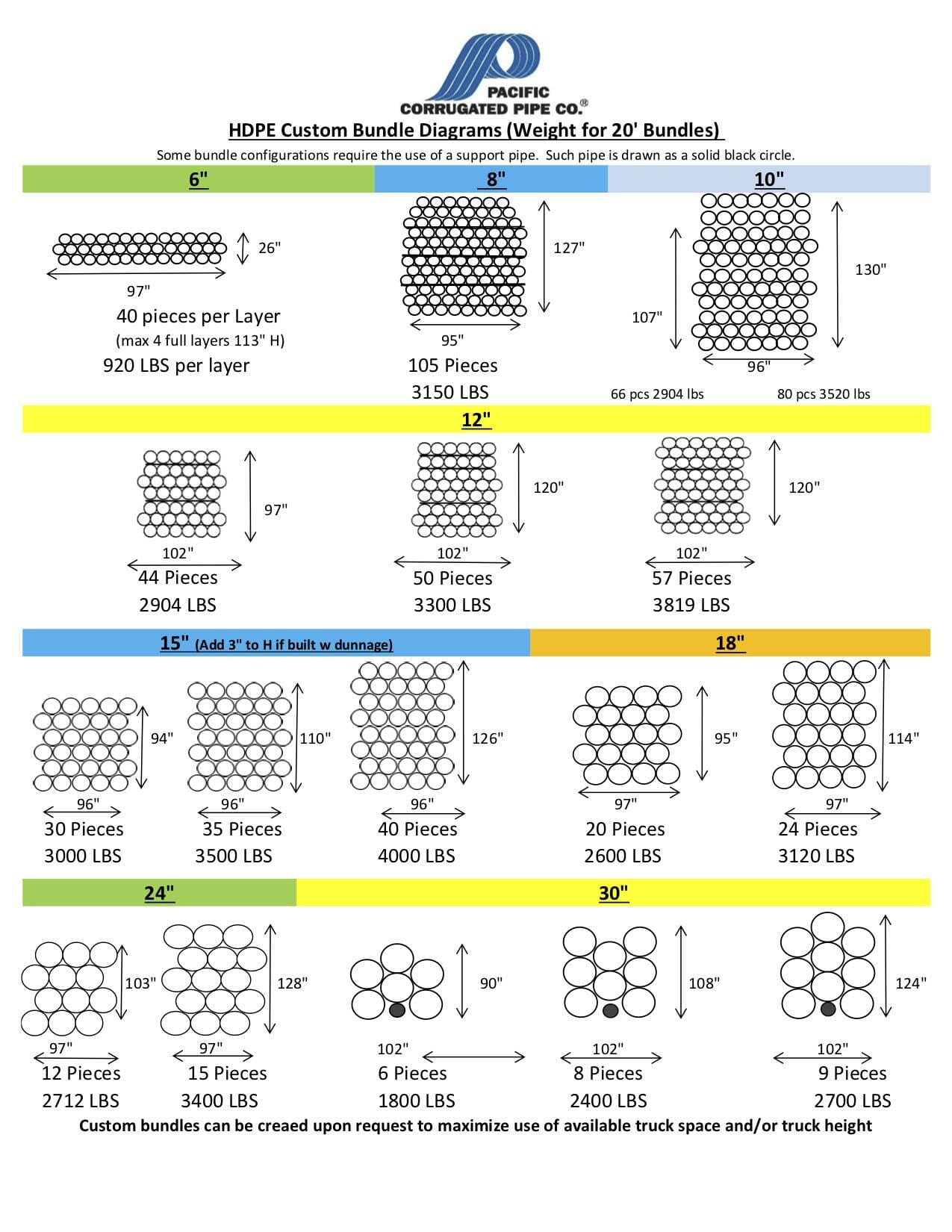

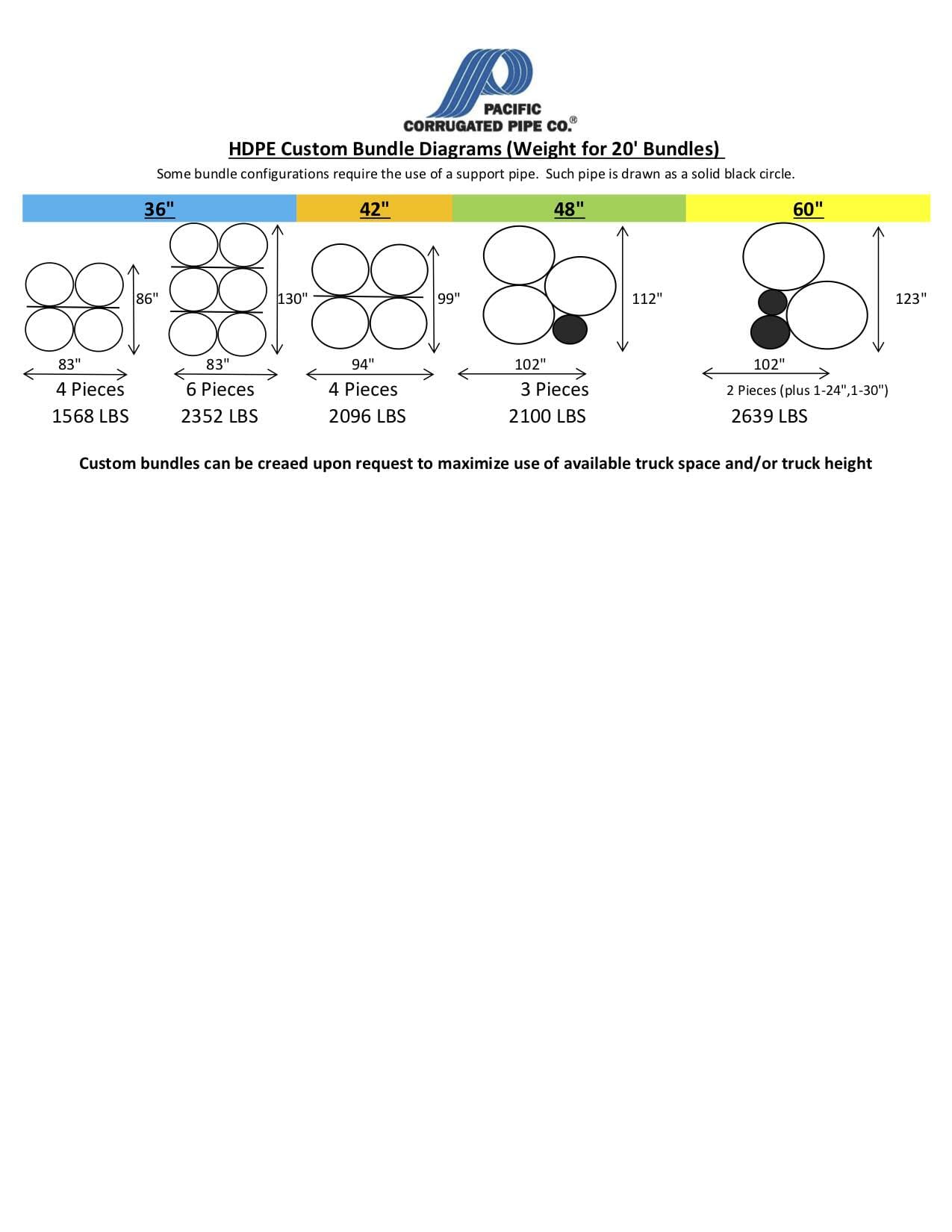

HDPE Bundle Information