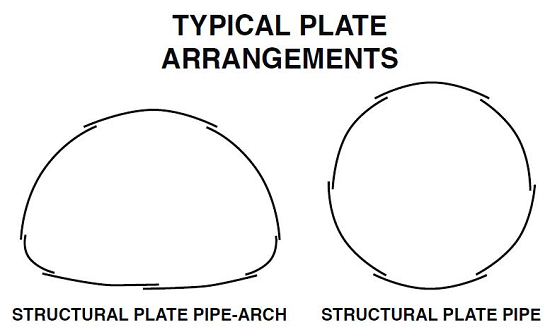

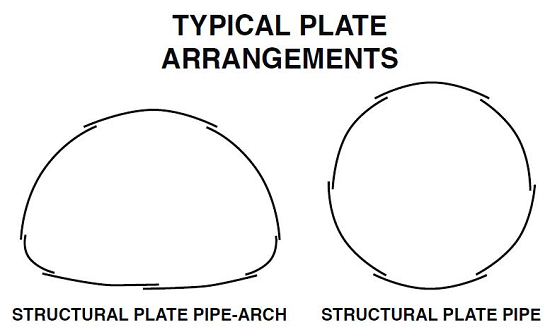

Unlike corrugated steel pipe, corrugated steel structural plate (SSP) is shipped to the site in curved plates and field assembled into its final shape by bolting.

Unlike corrugated steel pipe, corrugated steel structural plate (SSP) is shipped to the site in curved plates and field assembled into its final shape by bolting.

When spans exceed 12 feet, SSP may become the best corrugated steel option. Without shipment limitations associated with large conventional pipe, combined with increased thicknesses (through 1 gage) and stiffer corrugations, SSP expands the number of useful applications otherwise unattainable, and allows corrugated steel to be a viable alternative to the one or two options historically available in certain situations.

Pacific Corrugated Pipe supplies both steel and aluminum structural plate so engineers, developers and contractors have a choice. The lighter weight of aluminum plate creates a significant handling advantage. Aluminum is durable, offering excellent resistance against the effects of corrosion and abrasion.

Integrating an aluminum structural plate headwall into a selected culvert size and shape creates an installation friendly bridge replacement solution. With no rebar schedules, mix specifications, pours, frequent testing, cure times, etc., aluminum structural plate headwalls are an economic alternative to concrete.

The Benefits

- Lightweight— compared to other types of structures of similar size, such as structural steel or concrete bridges.

- Strong— the 6″ x 2″ (steel) and the 9″ x 2.5″ (aluminum) corrugations are significantly stronger than other corrugations of the same thickness.

- Easily installed— light equipment, simple tools and unskilled labor under adequate supervision can easily complete the assembly.

- Made to last— our steel structural plate is protected by a 3-ounce zinc coating, which gives the structure a long life with 50% more zinc than regular corrugated steel pipe.

- Conveniently delivered— plates are shipped in compact nested bundles, minimizing handling and freight costs.

Standard round corrugated metal pipe is used extensively in flood control, drainage and sewer systems because of its economic value, strength and durability.

Standard round corrugated metal pipe is used extensively in flood control, drainage and sewer systems because of its economic value, strength and durability.

Beveled End Sections are a practical and visually attractive way to complete an installation that includes a slope at either end of a culvert.

Beveled End Sections are a practical and visually attractive way to complete an installation that includes a slope at either end of a culvert.

Pacific Corrugated Pipe slotted drain pipe is a composite drainage structure consisting of a corrugated steel pipe with a fabricated linear steel grate protruding through the pipe wall, welded in place.

Pacific Corrugated Pipe slotted drain pipe is a composite drainage structure consisting of a corrugated steel pipe with a fabricated linear steel grate protruding through the pipe wall, welded in place.

Unlike corrugated steel pipe, corrugated steel structural plate (SSP) is shipped to the site in curved plates and field assembled into its final shape by bolting.

Unlike corrugated steel pipe, corrugated steel structural plate (SSP) is shipped to the site in curved plates and field assembled into its final shape by bolting.